Modular engineering focuses on integrating innovative design, new materials, rapid-deployment methods, and thorough testing to improve military shelter systems. This article analyzes the impact of these on shelter systems’ durability, efficiency, and performance in field conditions. It assesses the contribution of MIL-SPEC ECUs to system reliability and captures anticipated developments as we head towards 2026.

Military operations require shelters that adapt to changing operational needs and can be rapidly deployed, while withstanding extremely hostile conditions. Tent structures and rigid buildings impose significant logistical expenses and don’t meet these requirements. Modular engineering is a new approach offering scalable, adaptable, and robust resilient shelters.

This article analyzes the convergence of modular design principles with new materials, new deployment methods, innovative testing, and other factors to meet operational needs. It also looks into subsystems, such as mil-spec ecu electronics, which enhance system performance.

Table of Contents

ToggleThe evolution of modular design in military technology

Modern advanced shelter systems use modular design, plug-and-play technology, and modular lightweight military shelters. Rapidly deployable systems also become more flexible to meet mission requirements. As of 2024, according to Global Market Insights, the value of the deployable military shelters was estimated to reach USD 1 billion and grow within the following years.

Engineers expand or retract modular systems using prefabricated panels, foldable trusses, and standardized connectors. Structural modules can be added or removed, eliminating the need for complete redesigns for different mission objectives.

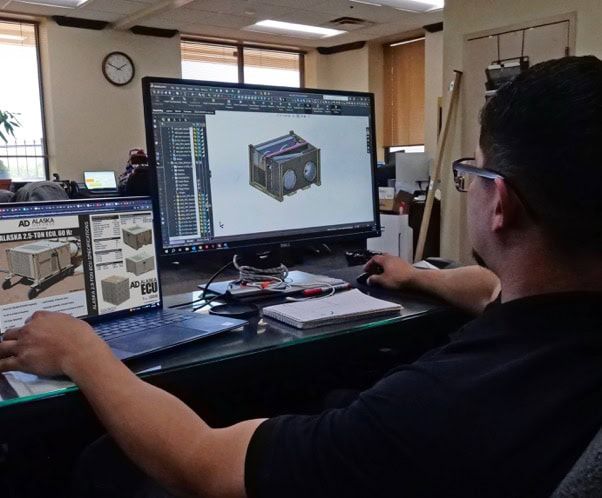

Many shelters also use military specification electronic components, which regulate temperature, protect against shock and vibrations, and ensure electromagnetic compatibility. Even power distribution, environment control and data routing systems of the modules are digitally governed by the military standard electronic components. These units readily integrate within different modules and can also be deployed to different mission theaters, which enhances the reliability and scalability of the design for military use.

The borrowing of modular architecture from both aerospace and telecommunications has matured in its defense applications. Modular shelters now serve as the cornerstone of contemporary operations, within which the building is once replicated, and reconfiguration in the field has become the norm.

How advanced materials enhance durability and mobility

Modern modular shelters extend well beyond the traditional steel frame and canvas covering. Modern materials offer strength, resilience, and a more favorable strength-to-weight ratio in addition to improved durability against corrosion, ultraviolet radiation, and abrasions. These include composite panels, hybrid alloys, high-performance polymer textiles, and sandwich structures.

For the modular shelters, fewer and lighter materials improve mobility and enable crews to transport larger shelters with lighter vehicles and more modules per load. Improved transportability and reduced logistical strain also allow handling rough terrains.

IMARC Group estimates that the global defense electronics market was approximately USD 176 billion in 2024 and would hit USD 278 billion by 2033. These electronics include advanced integrated rugged electronics, sensors, and control systems that have been designed to slot into the modular shelter architectures.

Military electronics and advanced materials are both meant to improve modular shelters. This optimizes shelter performance by increasing resilience in operations and reducing maintenance and deployment cycles.

Integrating rapid deployment with smart engineering

Speed of deployment is critical for operational success. Some modular shelter systems now ship as flat-pack kits and use minimal tools. Snap-fit connectors, quick-release latches, and foldable elements decrease setup time by 20 to 30% relative to older systems. pagedpspe.

Standardized power, HVAC, and data interfaces allow core modules to go online first, and specialized modules to be later configured as the mission requires. This increases flexibility and operational use in environments of high turnover and reduces downtime.

Rapid deployment also means shelters do not require complete reconstruction as mission priorities change, weather conditions become unforeseen, terrain shifts, or operational tasks evolve. Module rearrangements, or extensions, are possible without structural or operational compromise.

The role of testing and certification in mission readiness

Shelters must perform operational roles under extreme conditions; each module and subsystems are put under testing for vibrational shock, temperature cycling, moisture ingress, electromagnetic interference, and structural stress.

Electronics modules, such as mil-spec ECU units, must function fully under high mechanical load, extreme temperature, shock, and vibration. Meeting MIL-STD requirements for shock and vibration enables systems to control power, sensors and manage environmental control to be reliable.

Testing verifies that the combined modules’ interface points, connectors, and seals perform as expected. Guaranteed compatibility ensures military-standard interoperability, which translates to assured performance and dependable deployment in the expected theatre.

Looking Ahead

The combination of flexible modular designs, innovative materials, fast deployment techniques, and comprehensive testing transforms the capabilities of military shelters. Shelters are more flexible, quicker to deploy, and capable of sustaining operations in more difficult conditions.

Subsystems like military specification electronic control units are vital to the modules, providing advanced functionalities that are intelligent, dependable, and autonomous for each module. With advancements in materials and electronics, modular shelters will also operationally self-sustain.